Project Description

Gilsonite as Asphalt Modifier of Asian Gilsonite is used in HOT MIX with Asphalt so follow of this we called it HMA grade and wide range uses of our Gilsonite would be in Asphalt industries in large quantities for mixing with Asphalt as Modifier additive.

| Name | Gilsonite HMA Grade |

| Manufacturer | ARAS GILSONITE |

| Made By | Aras Gilsonite |

| Product Code | HMA |

Describtion of Gilsonite HMA

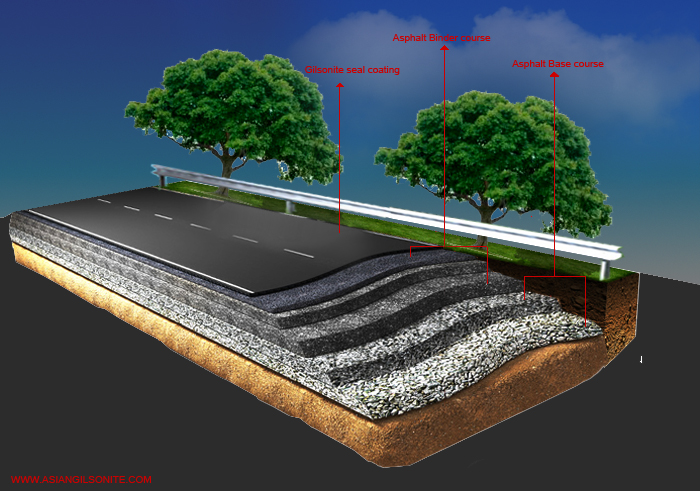

As you know asphalt is a composite material made by mixing sand and bitumen and in general, it is a mixture of stone materials with continuous granulation and adhesive material, which is usually bitumen and it has different types. here we want to mention that only by mixing gilsonite for making this kind of Asphalt or hot asphalt this product on roads will find very good quality and resistance and follow of this property of Gilsonite for HOT asphalt Europe and the USA are using Gilsonite in their Asphalt more than 50 years.

Gilsonite is known as one of the best materials used in making asphalt. The use of Gilsonite in this product increases the strength of asphalt against high temperatures in summer and low temperatures in winter, thus preventing the asphalt from changing shape with temperature changes. Another property that Gilsonite adds to asphalt is the increased adhesion of asphalt, which makes it easy to disassemble and leaves no cracks or crevices. Another feature that you get by adding Gilsonite to asphalt is the increase in asphalt resistance against the heavyweight of heavy vehicles. Today, even old road and street asphalt is covered with asphalt with Gilsonite additive, which is 20% thinner in thickness and has higher strength, and extends the life of old asphalt.

In general, we can say that it is an Asphalt modifier that can be mixed directly with hot bitumen and other asphalt materials in the asphalt manufacturing plant without additional equipment, the resulting mixture has excellent adhesion properties, high strength, and high performance and also would be water resistance too.

Asphalt always was the best option for streets, roads, and parking lots because it is a great affordable option that is easy to repair and will last for years but if we want to use it for many years it must have good Composition and only by mixing sand and bitumen you can except that it works for you for many years without any problems so it means that when it mixes with Gilsonite its lifespan will be longer and also it is sustainable because it can be recycled and reused. aggregates consist of processed mineral materials such as crushed stone, sand, gravel, slag, or various recycled materials. a cohesive mixture is formed when an adhesive is used to bind its aggregates together, and it is Gilsonite that is most often used as an adhesive.

Weather conditions are the first factor that plays a role in asphalt exhaustion and water, snow and freezing can cause significant damage during the season. With numerous snowfalls, sub-zero temperatures, and occasional blizzards, winter is one of the most difficult seasons in relation to different types of pavements and pavements. also, stagnant water is the enemy of asphalt all year round, but winter weather increases the bad effects due to freezing. we mentioned all of these items to say that only by mixing Gilsonite with it when you are producing it the road’s asphalt will have good resistance against all of these weather damages.

Asphalt Mix With Gilsonite Features

- High strength and durability compared to asphalt without Gilsonite

- It will be more resistant to deformation

- In terms of thickness, asphalt combined with Gilsonite will be less thick

- It will be much less sensitive to decreasing temperature and increasing temperature

- Due to the waterproof properties of Gilsonite, asphalt combined with Gilsonite is very resistant to water penetration.

- Gilsonite extends the life of roads and strengthens them

- Excellent adhesion to all surfaces like metal, concrete, galvanized, stone, wooden, isogamy

- Prevent freezing and erosion

- Moisture and thermal insulation

- High resistance to weather conditions of +100 to -20 degrees and no cracking due to sub-zero cold

- It does not flow due to high temperatures

- Resistant to UV rays of the sun

- No environmental pollution

- Very high resistance to possible shocks and cracks

- Preventing damage and corrosion of the surface due to acidic and alkaline chemicals and oil such as diesel and oil, resistance to water mineral salts

- Suitable for airport runways, highways, refineries, combined cycle power plants, university campuses, petrochemical plants, oil platforms, factories, heavy machinery equipment factories

Remember that using Gilsonite will help you to reduce the costs by about 20% in production and in the future also will reduce repair costs because as you know the costs of repair and maintenance are too high and only by mixing Gilsonite you will save all of these costs in future.