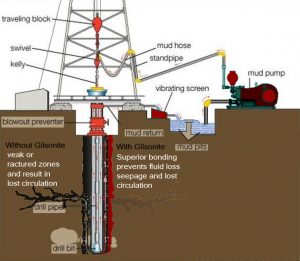

Drilling Fluids would be one of the important processes of Oil well explorations in the world. in these days and for better results, the companies who are working in this base must have some additives for fluid loss controlling one of the best additives for controlling the fluids loss of Oil Wells would be Gilsonite FLC grade of Asian Gilsonite it will increase the efficiency and strength of oil and hydrocarbon wells too.

Today, Gilsonite can be named as an integral component for mud drilling of wells, which reduces drilling fluids costs and improves drilling performance In addition, Gilsonite does not harm the environment and natural resources and would not be in contradiction with environmental protection laws.

Gilsonite FLC Grade prevents from damage to the oil well

Due to the chemical and physical composition of the materials along the walls of the oil well, Gilsonite creates a very strong insulator without permeability against drilling fluids.

Gilsonite FLC Grade unique property in terms of its compatibility with the oil wells and the flexibility of Gilsonite prevents fluid leaks and changes in oil wells in reactive clay layers even in the hot temperature of the lower elevation of the wells.

Gilsonite FLC Grade has been proven as a stabilizer to the wellbore

For drilling in pressurized areas, there is a need for different techniques to strengthen the well and drill fluids combined with Gilsonite.

Adding Gilsonite to drilling compounds has several advantages such as preventing fine fractures in drilling drills and reducing pressure on it, Keeping intact layers intact, Increasing the level of the filtering layer, Create an insulating layer continuously without breaking through the walls of the oil well.

Gilsonite FLC Grade is the best drilling material to prevent differential locking of the drilling machine

Gilsonite reduces the number of drill bits in high pressure and high humidity areas, minimizing pressure and improving moisture content, and increasing the life span of the drilling machine.

Gilsonite API Grade

Gilsonite API Grade refers to a specific grade of natural bitumen (asphaltite) that meets American Petroleum Institute (API) standards for use in oil and gas drilling fluids. It is primarily used as an additive in drilling muds to enhance wellbore stability, reduce fluid loss, and improve overall drilling performance.

Properties of Gilsonite API Grade:

High Softening Point: Ranges between 150°C to 220°C, making it stable in high-temperature drilling environments.

High Solubility in Oil-Based Fluids: Dissolves easily in organic solvents and oil-based muds.

Strong Bonding & Sealing Properties: Helps prevent shale swelling, sloughing, and wellbore collapse.

Low Ash Content: Ensures minimal contamination in drilling fluids.

Hydrocarbon-Based: Acts as a natural plugging agent for fractures and pores in rock formations.

Applications of Gilsonite API Grade:

Oil & Gas Drilling:

Used in water-based and oil-based drilling muds.

Improves filtration control and reduces differential sticking.

Helps stabilize shale formations and prevents wellbore collapse.

Cementing Additive:

Used in well cementing to reduce slurry density and improve compressive strength.

Asphalt & Road Construction:

Enhances asphalt binder performance, making roads more durable and resistant to deformation.

Advantages of Using Gilsonite API Grade in Drilling:

- Reduces Fluid Loss: Acts as a natural sealing agent to prevent excessive fluid loss.

- Prevents Wellbore Instability: Strengthens weak formations and reduces risks of shale sloughing.

- Environmentally Friendly: A natural hydrocarbon with minimal environmental impact.

- Cost-Effective: Improves drilling efficiency and reduces operational costs.

Suppliers & Availability:

Gilsonite API Grade is mainly sourced from Dubai and the USA (Utah), and is supplied in powder form.